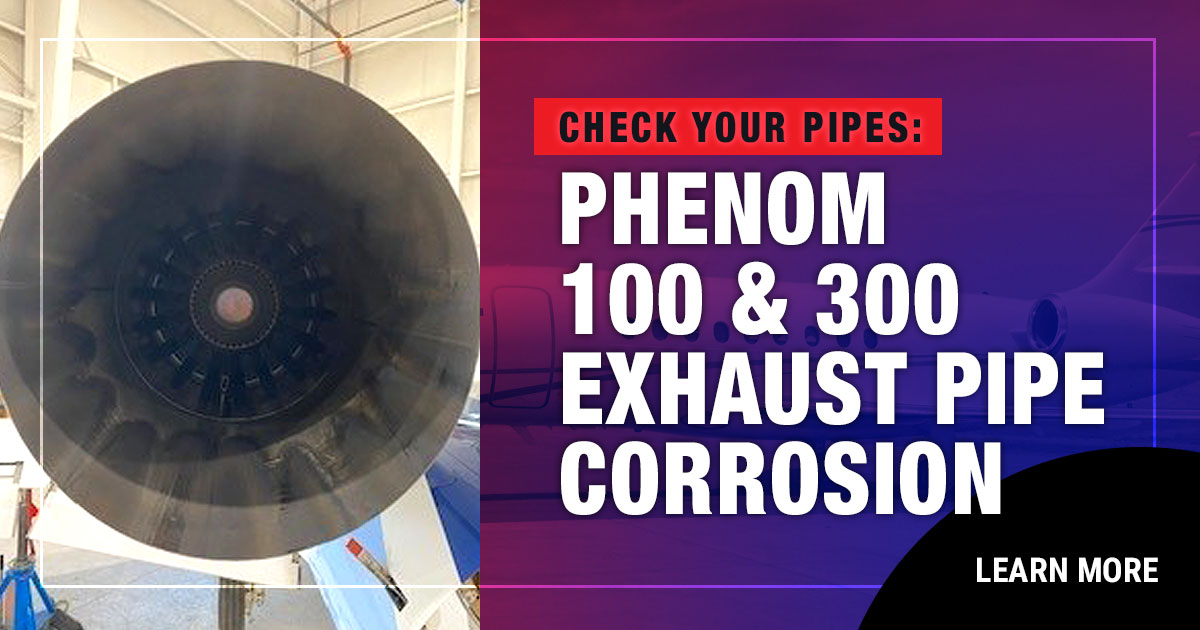

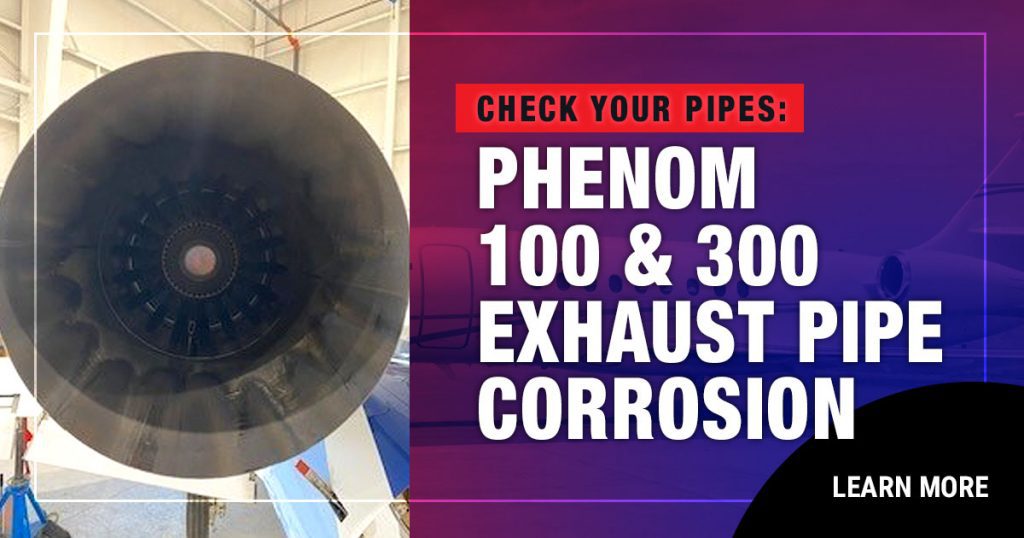

In some instances, the corrosion is severe enough to warrant the replacement of the entire exhaust assembly. Typically, if the corrosion is only located on the inner skin, not the exhaust cone support structure, West Star can replace the inner skin only. It’s ideal to catch the skin corrosion before it expands into areas of the support structure itself

Embraer is working to address reports of corrosion on the internal skin on the exhaust nozzle for Phenom 100 and 300 series aircraft. West Star Aviation has observed this directly in some instances, with surface corrosion building on the inner skin of the engine exhaust pipe. This condition should be assessed during routine engine exhaust case inspections that occur every 12 months or 800 hours.

West Star Aviation, as an Authorized Embraer Base Maintenance Center, has been working with Embraer to replace the inner skins of the exhaust assembly. The inner skin gets replaced with a new skin. This is a permanent repair. The new skin that is installed has a sulfuric acid anodizing finish to help prevent corrosion. Embraer is also currently reviewing an application using heat resistant paint.

With proper planning, this inspection and subsequent repair can be completed in approximately one week when parts are on hand. The repair can be performed at any of the four West Star Aviation full-service facilities: East Alton, IL (ALN), Grand Junction, CO (GJT), Chattanooga, TN (CHA) and Perryville, MO (PCD).

For more information on this or any of the other

Embraer capabilities, please contact any of the Embraer Specialists below:

Mark Crotty

Embraer Program Manager

(ALN)

Office 618.390.1114

mcrotty@wsa.aero

Michael Forehand

Embraer Program Manager

(CHA)

Office 618.258.8863

mforehand@wsa.aero

Joe Carr

Technical Sales Manager Embraer

(GJT)

Office 970.248.5279

jcarr@wsa.aero

Jeff Messmer

Technical Sales Manager

(PCD)

Cell 314.607.4069

jmessmer@wsa.aero

- Posted in App, Embraer Tips, News

- No Comments